ETO is an original equipment manufacturer (OEM) for EVs with an existing capacity to build 10,000 units per year.

ETO is an original equipment manufacturer (OEM) for EVs with an existing capacity to build 10,000 units per year.

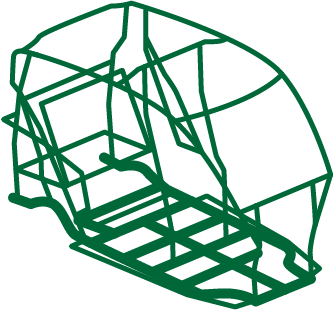

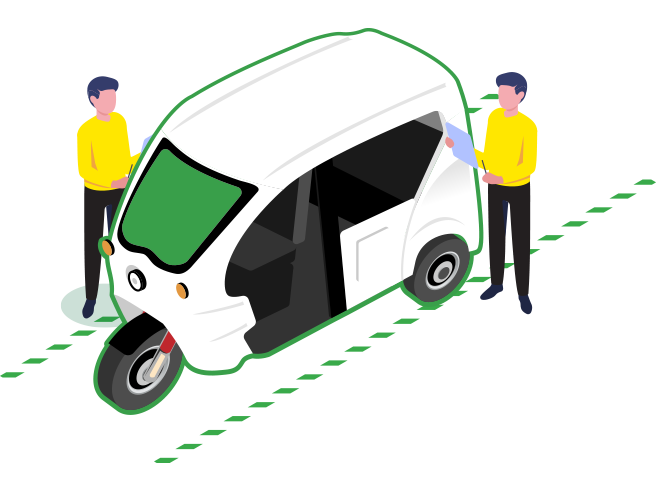

ETO is one of the first in the sector to provide a production technique that makes the body of our vehicle robust and highly secure. The alloy monocoque chassis is made of lightweight aluminium, which, when welded together, provides twice the tensile strength compared to other three-wheelers. This helps absorb twice the crash energy, making the occupants and the vehicle structure better protected in the event of a collision.

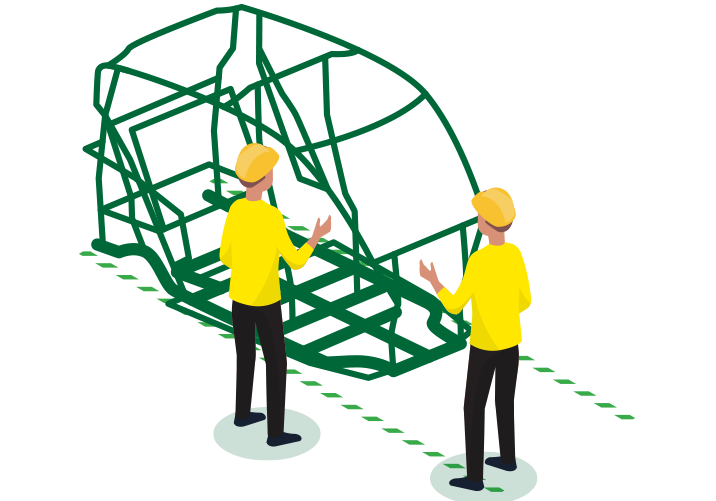

While the chassis is completely fabricated from scratch, various other components like the shock absorbers, front facia, roof, and wheels are parallelly assembled at the sub-assembly workstation. The inherent design of the vehicle is made using lightweight materials without compromising on durability. This means it uses less energy to accelerate, offering excellent vehicle efficiency.

This is where the final shape and structure of our EVs come together. The monocoque chassis, the sub-assembly components, battery, and seats are brought together and assembled at the main assembly line. Every vehicle is handcrafted at ten workstations by our engineers and checked for quality by our experts.

ETO is committed to providing its customers with quality assurance and reliable vehicles. Our specially trained experts and plant quality team conduct in-line in-depth checks at each workstation in compliance with national and international standards. From incoming materials to outgoing components, every part is assessed at two checkpoints. We also facilitate a third-party pre-despatch inspection by our after-sales service team to be in line with functional requirements and customer specifications.